Have A Info About How To Fix DC Bus Overvoltage

DC Bus Overvoltage Problem Page 3 Electrician Talk

Understanding DC Bus Overvoltage

1. What Exactly is DC Bus Overvoltage?

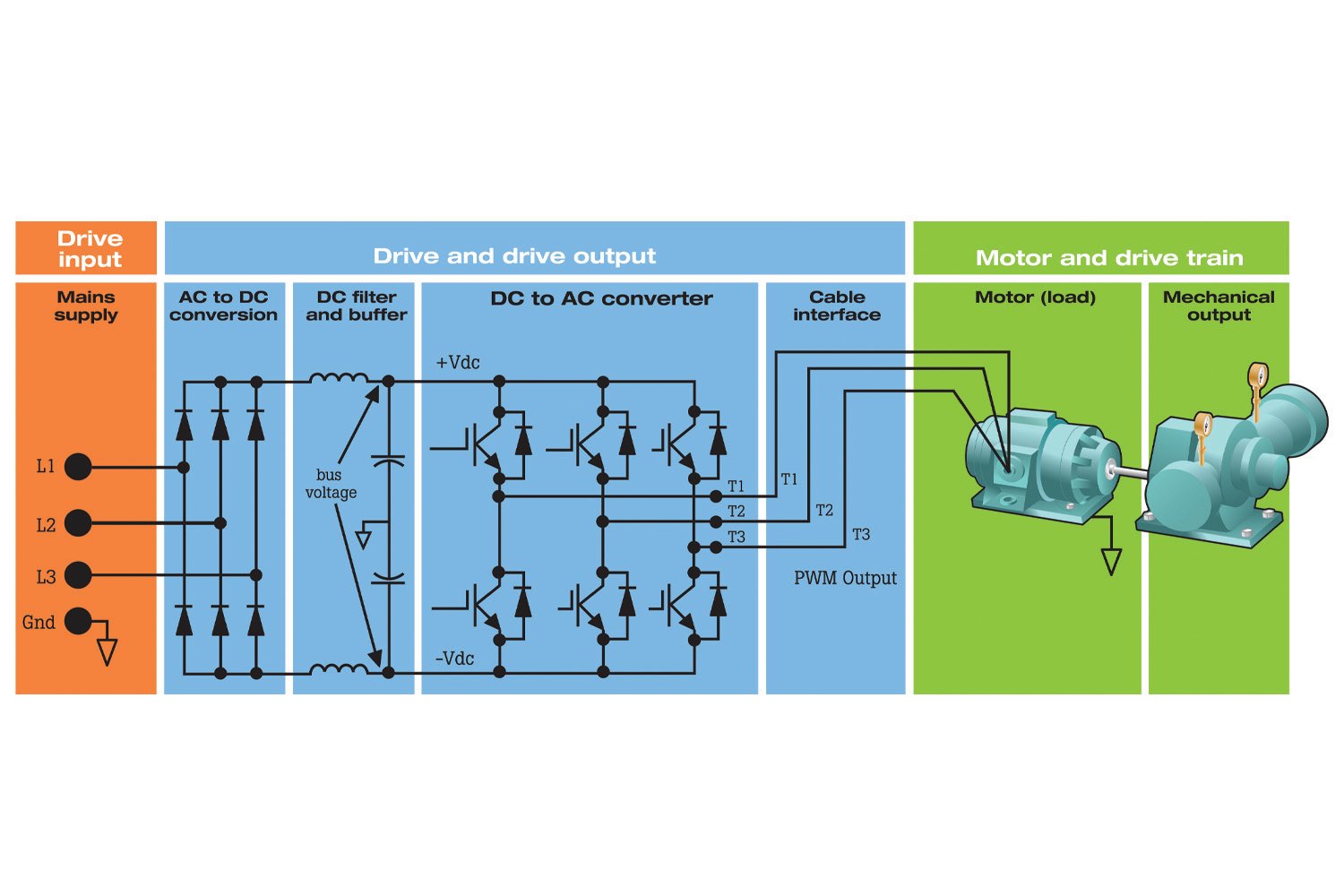

Okay, so you're staring at your equipment, maybe a Variable Frequency Drive (VFD) or some other power electronic device, and it's screaming about "DC bus overvoltage." What does that even mean? Well, imagine the DC bus as the main highway for electricity within your system. It's supposed to operate at a certain voltage, like a speed limit. When it goes over that limit — boom! — you've got an overvoltage situation. Think of it like your car's speedometer going way past the red line; not good!

This overvoltage isn't just some minor inconvenience. It can actually fry sensitive components, cause your equipment to shut down unexpectedly (hello, production delays!), and generally wreak havoc on your entire system. It's like a power surge, but instead of coming from the utility company, it's being generated within your own equipment. Not ideal, right?

Where does this excess voltage come from, you might ask? It's usually due to regenerative energy. Think of a motor acting as a generator when slowing down. This braking energy gets pumped back into the DC bus, raising its voltage. It's like trying to push water back into a flowing river; eventually, something's gotta give.

The severity of the overvoltage depends on several factors: the amount of regenerative energy, the capacitance of the DC bus (its ability to absorb that energy), and the effectiveness of any braking resistors or other energy dissipation methods in place. So, identifying the root cause is the first step in preventing your equipment from having an electronic meltdown.

2. Spotting the Symptoms

Knowing when you have a DC bus overvoltage issue can save you a lot of headaches (and money!). Its not always obvious, but there are a few telltale signs you should be on the lookout for.

First and foremost: alarms! Your VFD or other equipment will likely display an error code or warning message specifically related to DC bus overvoltage. Pay attention to these; theyre trying to tell you something. It's like your car's check engine light; ignoring it usually makes things worse.

Another symptom could be erratic or unexpected shutdowns. If your equipment is tripping offline frequently, especially during deceleration or braking, overvoltage could be the culprit. The system is basically protecting itself from self-destruction. This can be incredibly frustrating, especially if youre trying to meet a deadline, but remember, safety first!

Finally, keep an eye on performance. If you notice your motor behaving strangely, such as fluctuating speed or inconsistent torque, it could be indirectly related to DC bus voltage fluctuations. These kinds of performance dips can be really subtle, but theyre valuable clues for detecting a problem before it becomes catastrophic.

The Culprits

3. Regenerative Braking

As mentioned earlier, regenerative braking is often the primary source of DC bus overvoltage. When a motor decelerates, it acts as a generator, sending energy back into the DC bus. If this energy isn't dissipated effectively, the voltage on the bus will rise. It's like trying to fill a glass that's already full; it's going to overflow eventually.

Applications with frequent starts and stops, or those involving heavy loads with high inertia, are particularly susceptible to this issue. Think of elevators, cranes, or even high-speed conveyor systems. These applications demand a lot of braking power, which translates to a lot of regenerative energy.

The good news is that there are solutions for managing regenerative energy. Braking resistors are the most common method, but there are other options available, such as regenerative drives that feed the energy back into the AC power supply. Choosing the right solution depends on the specific application and the amount of regenerative energy involved. Its all about balance.

Besides applications, consider your motor load. If you have oversized motor or have improper tuning on the ramp-down, you're likely generating more voltage than your DC bus can handle. Consult a professional when deciding motor size.

4. Inadequate Braking Resistors

Even if you have braking resistors installed, they might not be sized correctly or functioning properly. A resistor that's too small won't be able to dissipate enough energy, leading to overvoltage. Its like trying to bail out a sinking boat with a teaspoon; you're going to need something bigger.

Over time, braking resistors can also degrade or fail. This can be due to overheating, corrosion, or simply wear and tear. Regular inspection and testing are essential to ensure that your braking resistors are in good working order. Think of it as giving your car a regular tune-up; preventive maintenance can save you from major problems down the road.

Ensure that the resistor's wattage and resistance values match the requirements of your drive. Also, check the wiring connections to the resistor. Loose or corroded connections can reduce the effectiveness of the braking system. Double check every connection is properly wired. This small maintenance can save you a large sum of money.

Finally, consider the duty cycle of your braking resistor. Some resistors are designed for intermittent use only, while others can handle continuous braking. If you're exceeding the duty cycle rating of your resistor, it will likely overheat and fail prematurely. It's important to choose a resistor that can handle the demands of your application.

5. Line Voltage Issues

Sometimes, the problem isn't internal to your equipment; it's coming from the incoming AC power supply. Fluctuations or spikes in the line voltage can directly impact the DC bus voltage. This can be caused by various factors, such as grid instability, power outages, or even nearby equipment that's drawing a lot of power. Its like a ripple effect; a disturbance in one part of the system can affect everything else.

A high or unstable AC line voltage can directly translate to an elevated DC bus voltage. While VFDs typically have some tolerance for voltage fluctuations, exceeding those limits can trigger an overvoltage fault. Its kind of like the straw that broke the camels back; the system can only handle so much before it gives up.

Consider installing a line reactor or other power conditioning equipment to mitigate voltage fluctuations and spikes. These devices can help to stabilize the incoming power supply and protect your equipment from damage. This can prevent damaging sensitive equipment.

Furthermore, regularly monitoring your incoming AC line voltage can help you identify potential problems before they escalate. A simple multimeter can be used to check the voltage levels, or you can install a more sophisticated power quality analyzer for continuous monitoring. Detecting issues early on can help you avoid costly downtime.

Overcurrent And Overvoltage Faults YouTube

The Fix

6. Braking Resistor Adjustments

One of the most common fixes for DC bus overvoltage is adjusting or replacing the braking resistor. The goal is to ensure that the resistor is sized correctly and functioning effectively to dissipate regenerative energy. Let's get this fixed!

First, verify the resistor's wattage rating. It should be sufficient to handle the peak regenerative power generated by your motor during braking. If the resistor is too small, it will overheat and fail. Think of it like wearing shoes that are too tight; uncomfortable and ineffective. When in doubt, go bigger. A larger resistor can handle more energy.

Also, check the resistance value. Too high of resistance may not dissipate energy fast enough. Also, inspect the resistor itself for any signs of damage, such as cracks, burn marks, or corrosion. Replace the resistor immediately if you notice any of these issues.

Don't be afraid to experiment with different resistor values and wattage ratings to find the optimal solution for your application. Start with the manufacturer's recommendations and then fine-tune from there. This is not a "one-size-fits-all" situation, and you may need to tweak things to get it just right.

7. Regenerative Drive Implementation

If braking resistors aren't cutting it, or if you're looking for a more energy-efficient solution, consider implementing a regenerative drive. These drives can feed the regenerative energy back into the AC power supply, rather than dissipating it as heat. It's like turning your waste into a resource.

Regenerative drives are more expensive than braking resistors, but they can save you money in the long run by reducing energy consumption. They also reduce heat buildup in your control cabinet, which can improve the reliability of your equipment. Win-win!

Consider if your application requires a large amount of braking energy. If you have a frequent start and stop application, you might want to use regenerative drives.

This solution isn't for everyone. Consider the initial costs of regenerative drives vs long term savings and its effectiveness for your particular application.

8. Line Reactor Installation

As we discussed earlier, line voltage fluctuations can contribute to DC bus overvoltage. Installing a line reactor can help to stabilize the incoming power supply and protect your equipment from voltage spikes and surges. Think of it as a buffer between your equipment and the outside world.

Line reactors are relatively inexpensive and easy to install, making them a good option for mitigating voltage-related issues. They can also help to improve the power factor of your system, which can further reduce energy consumption. It's like getting two birds with one stone.

Don't cheap out on this step! Ensure you're buying a line reactor that is rated for the voltage and current of your system. A mis-match can result in damage or premature failure. Also ensure it is properly grounded to prevent stray voltage from impacting your system.

This is a common solution for variable frequency drives to help stabilize voltage spikes and surges.

Preventative Measures

9. Regular Maintenance and Inspections

The best way to deal with DC bus overvoltage is to prevent it from happening in the first place. Regular maintenance and inspections can help you identify and address potential problems before they lead to equipment failure. Treat your system with care, and it will treat you with care too.

Regularly check the braking resistors for signs of damage or degradation. Test the resistance values to ensure they're within the specified range. Inspect the wiring connections for any looseness or corrosion. Think of it as giving your equipment a regular checkup; early detection can prevent serious complications.

Additionally, monitor the DC bus voltage levels to identify any trends or anomalies. A sudden increase in voltage, or frequent overvoltage trips, could indicate an underlying problem. Keep an eye on those voltage readings, and don't ignore any warning signs!

Lastly, ensure that the cooling fans and ventilation systems are working properly. Overheating can exacerbate many electrical problems, including DC bus overvoltage. Keeping things cool and comfortable can go a long way in preventing issues. Its like making sure your computer doesnt overheat; a little bit of cooling can save you a lot of trouble.

10. Proper System Design and Configuration

A properly designed and configured system is less likely to experience DC bus overvoltage issues. This includes selecting the correct components, sizing the braking resistors appropriately, and configuring the drive parameters correctly. Start strong, and you'll be less likely to stumble later on.

Ensure that the motor is properly sized for the application. An oversized motor can generate excessive regenerative energy, leading to overvoltage. Also, configure the drive parameters for optimal braking performance. This includes adjusting the deceleration rate and enabling any built-in overvoltage protection features.

When in doubt, consult with a qualified engineer or technician to ensure that your system is designed and configured correctly. They can help you identify potential problems and recommend solutions. Think of it as getting a second opinion from a doctor; it's always good to have another set of eyes on the situation.

Don't skimp on the design phase. Investing time and effort upfront can save you a lot of headaches and money down the road. A well-designed system is a reliable system.

11. Staying Informed

Technology is constantly evolving, and new solutions for managing DC bus overvoltage are always being developed. Stay informed about the latest advancements and best practices to ensure that you're using the most effective methods for protecting your equipment. Knowledge is power!

Attend industry conferences and workshops to learn from experts in the field. Read trade publications and online forums to stay up-to-date on the latest trends and technologies. Dont be afraid to ask questions and share your own experiences with others.

Contact your equipment manufacturers for updates and recommendations. They often have specific advice for addressing DC bus overvoltage issues on their products. It's always a good idea to go straight to the source.

In the end, preventing DC bus overvoltage is a combination of diligence, careful design, and staying informed. Stay proactive, stay curious, and your systems will likely run much smoother for much longer.

Junli Wu On LinkedIn One G5 Drive Showed "DC Bus Overvoltage" Right

FAQ

12. Q

A: Ignoring a DC bus overvoltage fault is like ignoring a fire alarm — it's likely to lead to bigger problems. Prolonged overvoltage can damage or destroy sensitive components in your equipment, leading to costly repairs and downtime. The best course of action is to address the issue promptly and properly.

13. Q

A: While you can technically use a different resistor, it's generally not recommended unless you have a thorough understanding of the electrical characteristics of your system. Using the wrong type of resistor can lead to inadequate braking performance or even damage to your equipment. Stick with the manufacturer's recommendations whenever possible.

14. Q

A: The frequency of inspections depends on the severity and frequency of braking required, but it's a good idea to inspect your braking resistors at least once a year. In demanding applications, you may need to inspect them more frequently. Regular inspections can help you identify potential problems before they lead to equipment failure.